MEDEZE Group officially signs a purchase agreement with Shibuya Corporation, a leading technology innovator, to acquire an automatic cell cultivation system. This smart solution will bolster the capabilities of MEDEZE's new state-of-the-art cell bank facility. With system delivery expected by June 2026, it further cements MEDEZE's position as a frontrunner in advanced stem cell solutions across Thailand and the region.

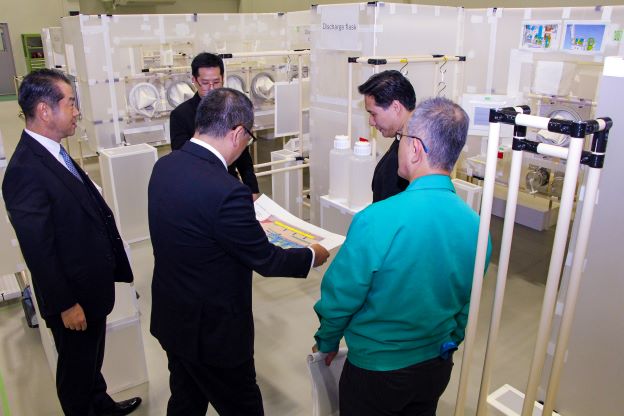

Dr. Veerapol Khemarangsan, CEO of MEDEZE Group Public Company Limited (MEDEZE), announced the collaboration with Shibuya Corporation, who is one of the leaders in medical technology research and development. The cutting-edge smart system will be installed at MEDEZE’s new cell bank facility, which will expand services to include the storage of stem cells derived from umbilical cord tissue, adipose tissue, umbilical cord blood, and hair follicle cells. Expected delivery by June 2026, this innovation underscores MEDEZE’s leadership in developing and providing groundbreaking stem cell solutions both in Thailand and the ASEAN region.

Meanwhile, Mr. Hidetoshi Shibuya, representing Shibuya Corporation (SHIBUYA), highlighted the exceptional capabilities of MEDEZE as Asia's largest and most experienced and fast-growing mesenchymal stem cell bank. The automated cell cultivation system that SHIBUYA offers will enhance cell storage capacity and cost-efficiency, as well as minimizing reliance on medical personnel, effectively addressing the shortage of specialized cell cultivation experts.

Said system is considered the world’s first automated cell cultivation for stem cells. It integrates sterile environmental control technology, cell production technology, and automatic transportation technology. The operation system consists of Cell Processing Unit (CPU) which fully automates all cell cultivation from cells delivery, media replacement, to culture under sterile conditions; Incubation Unit which controls temperature and moisture for each individual cell owner in approximately 100 independent micro-incubators units to reduce contamination risks and ensure optimal environmental conditions and; AiV Unit which works to transport each batch of cells via Autonomous Mobile Robots (AMRs) using AI optimization. These three components operate together seamlessly and automatically record production data without the need for intervention from medical personnel, thus increasing cells storage efficiency and reducing contamination risks.

“We are committed to develop and employ cutting-edge technologies to increase cells storage efficiency according to international standards. Elevating safety of cells storage system, which is a key component in cells banking, will help reduce risks from human error as well as enhancing cost-efficiency which enable reliable and high-quality cells production and storage, as well as safer service procurement and more reasonable pricing.